The Latest

Filter by Topic

Filter by Type

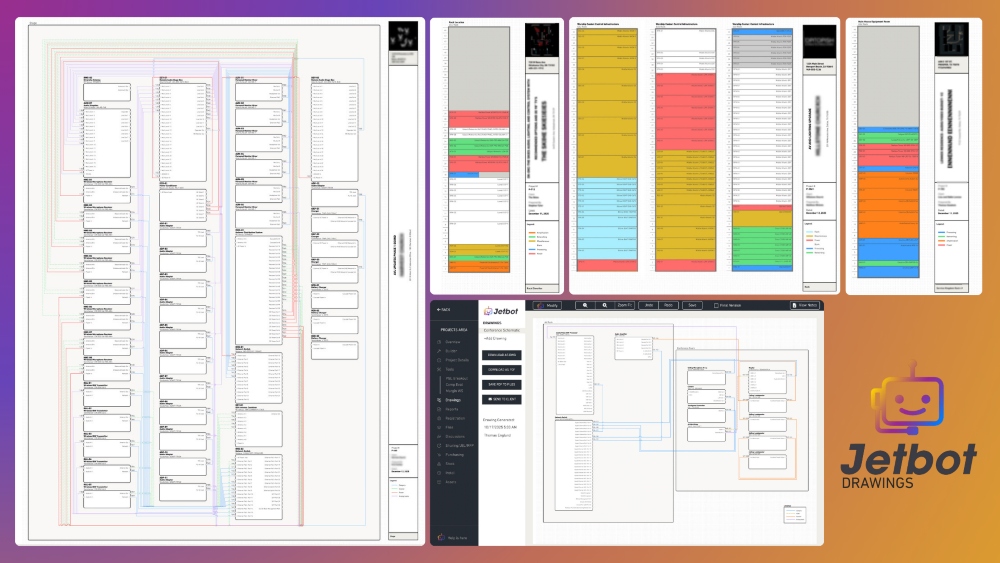

Jetbuilt to Expand Jetbot Drawings at ISE 2026 with AI-Generated Schematics

The Jetbuilt platform adds AI-generated rack elevations and floor plans to Jetbot Drawings, aiming to reduce drafting time…

News January 8DoorBird Adds Native Crestron Home Support for D11x Series

The company has stated support for the D18x series is on the way with no concrete date announced.

Briefs January 8Azione’s Patrick McCarthy on What Will Define Success in 2026

Recurring revenue, energy management, and operational discipline emerge as key themes for the year ahead for Azione's Patrick…

News January 8Unique Podcast Studio Drove Conversations at CEDIA Expo/CIX

A podcast studio inside a VW ID. Buzz became a hub for candid conversations on lighting, design, and…

News January 7Lutron Launches DIY Caséta Smart Wood Blinds With Automatic Sun-Based Tilt

Lutron Electronics has expanded its Caséta Wireless portfolio with the introduction of Caséta smart wood blinds, a new…

Briefs January 7WAC Appoints Chris Bruno as Western Business Development Manager for Integrator Channel

“Chris, a.k.a. Bruno, comes to us with an enormous amount of CI experience, including a background and reputation…

Briefs January 7Chamberlain Group Expands Beyond the Garage with myQ Secure View 3-in-1 Smart Lock

Chamberlain's myQ Secure View combines a camera-equipped smart lock with 2K HDR video and multiple options for fast…

News January 7GE Lighting Light + Form Series Adds Sculptural Aesthetics to Brand’s LEDs

Matter-ready smart shades and sculptural lighting signal GE Lighting’s push toward simpler installs, broader interoperability, and design-first smart…

News January 7Eve Expands Matter-over-Thread Lineup With Eve Thermostat at CES 2026

Eve's local-first smart thermostat debuts with Matter support, Thread connectivity, and no cloud dependency.

News January 6