Last time, we highlighted how AOC manufacturers are increasingly responding to the demand for more reliable products. Our first objective was to understand the design and cost expectations of module companies, a crucial starting point for all manufacturers. Now, we’re going to look at what we look at over at DPL Labs to measure the performance of these new AOC products, starting with light conversion methods.

Considering different distances was essential. At each distance, we applied comprehensive tests, including new procedures identified during various case studies. This process required the consideration of several variables: conversion method; types of parts used for each method; levels of sophistication; power management; and thermal byproducts.

Design aspects, such as the type of silicon (IC) used and the degree of control manufacturers have over it, are critical. Our study found modules ranging from highly sophisticated to extremely basic.

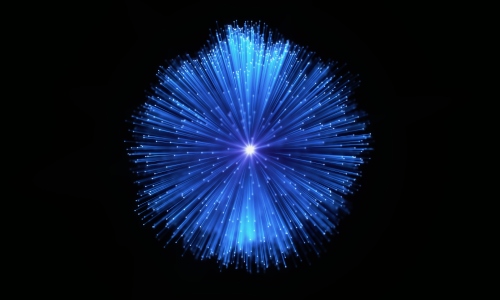

A conversion apparatus is needed to convert electrical energy to light energy. This is accomplished by modulating a Laser Diode, which couples its modulated light output to some form of optical fiber. When this signal arrives at the receiving end of the cable, it is converted back to electrical energy by photodiodes.

There are basically three methods used for light conversion within an AOC.

Channel-by-Channel Converter

The most economical and least sophisticated approach for light conversion in an AOC is the direct channel-by-channel converter. In this method, signal modulation is introduced into the cable assembly and immediately coupled to an electronic component that mirrors the input modulation using light energy from a laser diode (Fig. 1). This shows four channels entering from the input side of the cable. These channels are converted to light on the output side but in an unbalanced format.

This is common because the balanced differential channels used in digital video enhance the signal-to-noise ratio. Since optical fiber is immune to noise, maintaining this balanced driving method is unnecessary, which helps reduce costs. System telemetry and power are sent downstream on conventional copper wires. Although this is a direct way of supplying these signals, the copper channels can have drawbacks, such as signal degradation.

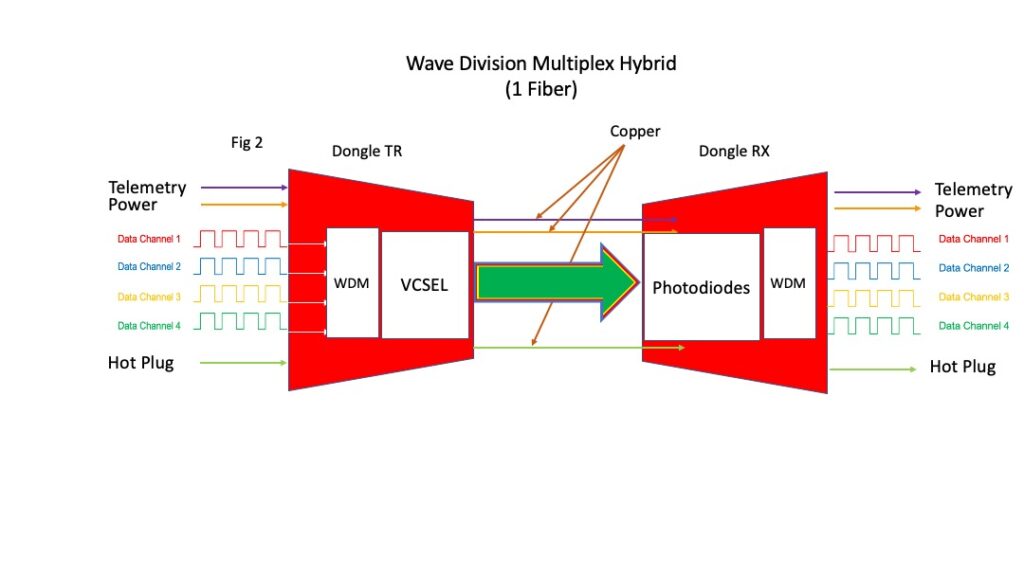

Wave Division Multiplex Converters (WDM)

A bit more expensive and typically found in a separate housing (Dongle), these can send video signal data over just one optical fiber (Fig. 2). This method eliminates the need for discrete lasers. WDM converters typically have better overall throughput and can generally achieve longer distances. However, they can still use copper to send all the system’s telemetry, which can be vulnerable to degradation.

Advanced WDM with HDMI Transmit and Receive Electronics

At a greater cost and a dongle form factor, WDM can be enhanced by incorporating HDMI transmit and receive electronics. This makes them more expensive compared to the previous methods but yields excellent results when administered correctly.

Instead of the signal directly entering the light converters, it first goes through an HDMI transmitter, similar to those found in typical repeater products. Here, the entire HDMI system signal is processed, utilizing features provided by HDMI chipsets such as EDID, HDCP, CEC, and various status control attributes. Essentially, both the transmit and receive chipsets work in tandem.

While this process is impressive, it can also introduce system issues due to its additional influence on the telemetry side, unlike direct light converters where signals are passed through via copper. Thanks to the advanced transmit and receive electronics, these converters operate harmoniously, consistently demonstrating high performance and reliability.