Proving that even the smallest details matter, Alloy, a San Francisco-based software company, is showing the manufacturing community the importance of efficient inventory management.

Alloy describes itself as a digital-native company that equips consumer goods companies with a software platform that provides real-time data to help manufacturers meet the instant demands of dealers.

Explaining why Alloy’s subscription software should be an important tool to manufacturers, Adrienne Alterman, regional sales director for Alloy, says the company is working to help manufacturers change the way they view information.

“We are trying to provide a global view of their inventory,” she says.

“Inventory management is very important—it is one of the top priorities for manufacturers. There is a saying that says the, ‘state of the warehouse is the state of sales.’ Understanding where the inventory is and how long it is going to take to get to the U.S. and consumers is important to manufacturers.”

Drawing on her decade of experience in the manufacturing community through past positions at top audio brands such as Bowers & Wilkins and YG Acoustics, Alterman says that traditional tools aren’t automated.

Alloy’s solutions build on traditional software tools, which in some cases can date back to the 1980s by providing users with a direct connection to their inventories in real time.

“Rather than using spreadsheets and connecting those spreadsheets, which takes time to compile that information. There hasn’t been a tool out there to automate all of those manual labor processes. Alloy automates all of those processes,” she notes.

Alloy Software Facilitates Communications Between Manufacturers and Retailers

Another aspect of the Alloy platform that modernizes the way manufacturers manage their inventory supplies and improve their ability to respond to dealer demand is the two-way communications the software enables.

Alterman points that only recently—the 1990s—Walmart became the first retailer to share its inventory levels with its manufacturing partners. Once Walmart started to share its information she continues, other retailers followed.

The problem she emphasizes is that even with this greater level of cooperation between retailers, inventory management was still mostly an analog process that required constant cross referencing to get relatively accurate information.

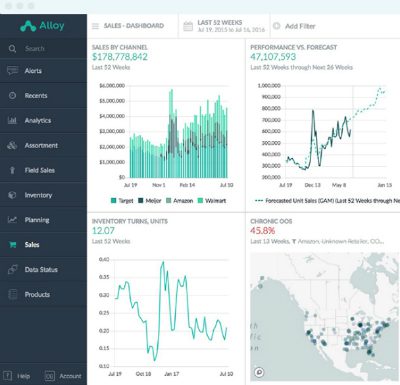

Alloy streamlines this process through prebuilt integrations that automatically gather this data from all your retailers and channels, no matter what format into a single platform.

The software eliminates the time-consuming process of combining of spreadsheets and it provides real-time information that users can manipulate in a dashboard to provide the inventory information manufacturers and retailers require.

She also says that beyond, the outdated tracking methods used to report inventory numbers, newer factors such as the growing power of retailers such as Amazon are also impacting the way retail industry does business.

Alterman explains that retailers often use their own methods to track and manage their inventories. She says that for example one retailer may use UPC codes and reorder an item every time a consumer purchases a particular item.

However, others may use different methods, but retailers inventory methods don’t matter to Alloy because it ultimately acts as a “calculator” that gathers data, while providing tools to manipulate that data to best suit the user.

Adding to the problems associated with traditional inventory tracking methods Alterman says is the results of using historical-based ordering procedures.

Summarizing historical-based ordering, she says that most companies work off forecast plans based on the previous two years of data. The problem with this approach is that looking at snapshots of the past does not accurately portray what is happening in the present.

Related: Software Yields 35% Boost in Employee Productivity

Through its real-time number reporting Alloy can provide manufacturers numbers that better represent the current purchasing trends of consumers.

“The reason Alloy can do that is the data it has on the inventory is where the numbers actually are. Having current, up-to-date data users can adjust their demand plans for what consumers really want,” she states.

“This can save retailers from having discount sales on overloaded inventories.”

Subscription Service is Fairly Priced

Alloy enters the market at a time when competition between software companies is at an all-time high.

Providing a solution that is competitively priced and value added for users, Alterman says Alloy is a subscription service with a one-year minimum contract. Providing the value-add proposition component of the service, she says Alloy does not limit the access of users.

“Alloy should be a source of truth, so to support that we give users access for as many people as possible,” she comments.

“From CEOs to salespeople can have access to the tool without having additional fees.”

Clarifying who exactly the software is intended for, Alterman adds that Alloy is for manufacturers and retailers with multiple locations. She says alloy can work with small dealers, but its prebuilt connectors are designed for national retailers like Amazon.

Read Next: 5 Reasons to Use End-to-End Software for Running an Integration Business

Moreover, the software can be used by brick-and-mortar and e-commerce retailers, and it is capable of providing global inventory figures, which makes Alloy a unique tool for manufacturers and retailers.

“There are few competitors. There are companies that do one or two things that we do. Some companies automate the data. Another company may generate charts to present to a buyer,” adds Alterman.

“So, there are different competitors, but no one is doing the creating true demand and providing forecasts and demand plans for retail partners. We provide the ability for them to run their business. We provide the information that manufacturers are typically blind to. Taking it a step further, we can manipulate that data to allow manufacturers to act on that information.”