Something new always comes up, you can bank on it. Unlike so many HDMI interoperability issues that are somewhat easy to identify, this instance was not — and nobody knew until DPL got its hands on it. Here’s what happened.

As with many cable providers, products are sent into DPL Labs for testing. They can follow a few options. If the provider is a member of DPL, they get to send their cable products in for a pretest so they don’t get stung paying all that money to the emissions people for approval in case their cable didn’t have an extremely good chance of making it. Then there are non-members, who send their products to our sister company InVisions Technology for testing and pay a fee. OK, that said, let’s dig into the meat.

This cable provider is a DPL participant and was able to have the cables pre-tested. We put these samples up in the queue and ran the first set of 12G eye patterns. The eye was formed but it looked a bit odd, as if someone took a hammer and smacked it right in the middle of the waveform. The product still achieved minimums, but with this kind of shape it was destined to be problematic in the field.

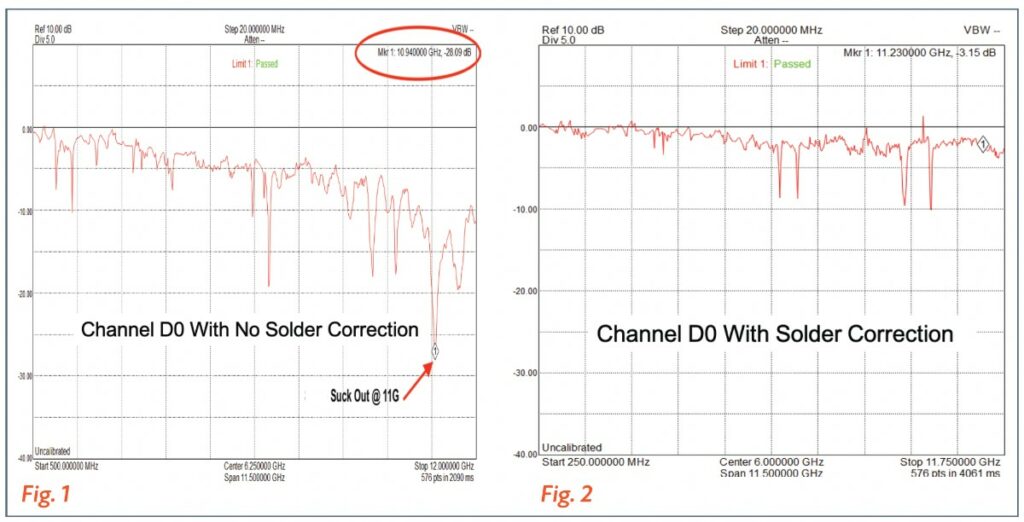

Digging a bit deeper, we ran frequency domain tests with a variety of S Parameters and extra DPL stress analysis functions. There it was — a 28dB suck-out at 11G (see Fig. 1). Now what you have to remember is that most of the energy in this transmission is down toward Nyquist, about 6G, but this caused response issues that were just too dangerous. Turns out almost all the samples we received were the same way. But why?

This was a doozy. Where do you even start? As usual, by ripping up the cable and inspecting the wire layout and its sub-assemblies along with the connector itself. These cables were soldered with automation, so you would have thought all was good. It turned out the ground shield over the connector assembly had an itty-bitty pin hole at one end that was common among most of the sample cables. Trust me, I did not find this; credit goes to one of our super “Black Magic” RF engineers who managed to detect it.

The pin hole created a mechanical L/C filter shunt at 11G, reducing the output by 28dB. We re-soldered the shell with some heavy amounts of silver solder flowing over the copper foil, drowning the shield in solder. Fig. 2 shows what happened to the signal response after the reflow of solder — a huge improvement in response and performance.

Needless to say, we informed the DPL member and provided a detailed report as to what was discovered and the procedure on how to correct the problem. The cables were never sent for emissions.

A change in production procedures would have to be made, not only in the process but with the automation system building the devices. We shall see effectiveness when the cables come back.

This just demonstrates the complexity of these products when you start running data rates as high as 12G per channel. The higher the data rate gets, the more vulnerable the interface becomes. Details in the manufacturing process must be kicked up a notch today. One minor slip-up can introduce field interoperability problems all over the world.