As we open up the 48G HDMI can of worms, an overflow of data spills out, particularly related to changes in the transmission line.

Transmission lines are specialized cables used primarily for high frequency signaling due to its natural characteristic of radiating signal energy into the air (like an antenna) as it moves over the 30KHz level. This characteristic is not constrained to just cable but also to PCBs (printed circuit boards). In fact, as products moved into these higher frequency signals PCBs had to take on a new look with different configurations and materials to maximize their signal throughput similar to any other cable.

Every time that data rate increases (especially a big one like with Rev 2.1) and is placed on a transmission line, it just can’t help but to create new artifacts.

Again, be it a cable or a PCB, the chemistry and physics are the same and must be treated as such. And the same rules apply to fiber transmissions due to PCBs used within these products.

Our new test instruments are quite a bit more sophisticated than instruments of the past — only because as the data rate moved closer to 50Gbps the offerings become somewhat selective from a small group of firms. Substantial research needs to take place to find such instruments and a company willing to customize it for your needs. The new test instruments will undoubtedly take time before we understand all of the myriad capabilities.

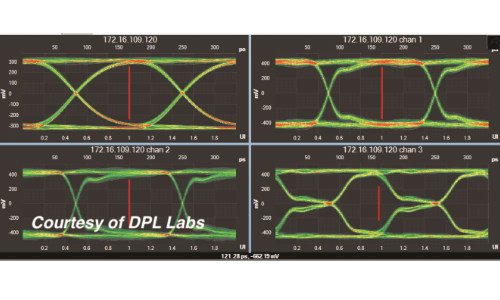

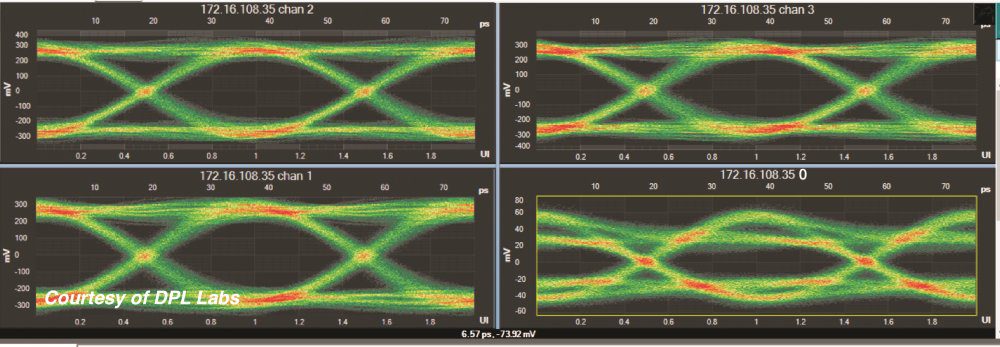

With this new suite one of the first things we did was sample some of the 48G HDMI cables sent in. The new oscilloscope images (pictured) are unique to this instrument and allow for some pretty accurate study, examining all four data lanes at the same time. Clearly, as we increased the data rate from 6Gbps to 12Gbps this sample showed signs of trouble with a high amount of distortion compared to a typical eye pattern.

We typically get five samples for each DPL-approved product; unfortunately, all five cables tested the same. We even went back into loop back mode to verify the instrument was not producing erroneous waveforms. Nope, it wasn’t that. After further review we discovered that stripping the cable down to its individual lanes still showed no sign of any disfiguration.

We then started dissecting each twin axe lane only to find out that by changing its topology within this particular lane (L0) the waveform was affected and with certain changes to its form a big improvement was revealed. It’s somewhat scary to think this cable was only a half-meter long! Since cable is often put up in 3,000-meter spools it was more than likely the entire spool was affected and probably should have been discarded.

This brings up the need for competent monitoring at the manufacturing level for any product being built to support these high data rates