The very first place to start if you want to design reliable, well-performing systems is grounding and surge suppression. While there have been countless articles written on this subject in other publications that just don’t add up, I’ll make sure that doesn’t happen here, and will lay out the whole thing for you.

In truth, a grounding system is the difference between a reliable system and complete destruction, and by itself, if improperly implemented, can cause that destruction. The need for rebooting, parts replacement, erratic performance and much, much more.

In the grounding and surge protection world, the most important thing to have is a single point grounding system. That means every cable, i.e. phone, cable TV, satellite, power, camera, landscape lighting, it all needs to have its ground connected to the incoming power service entrance ground rod without deviation. It doesn’t mean that the phone line comes in 40 feet away and the provider ran a small green grounding wire up and down to get to the ground rod.

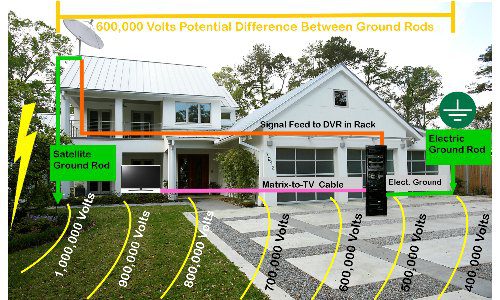

This is why we need a single point system: When a lightning bolt strikes, the voltage and current don’t just go into the ground and it’s over. The energy travels in all directions dissipating over a large area (see Fig. 1). As the current travels across and in the ground it dissipates. The strike point may start out at 1,000,000 volts and as it travels, its voltage lowers. The rate of dissipation is dependent on the composition of earth material (dirt, mud, rock, water, and salts).

Now imagine an antenna, pool controller or satellite dish at one end of the house and the electrical entrance on the other. Usually, somebody installed a separate ground rod at the pool equipment and antenna/satellite dish location. As the voltage decreases across the distance between the 2 rods, a potential difference of hundreds of thousands of volts appears across the rods, (in Fig 1, six hundred thousand volts), so it is easy to see that electricity wants/IS going to flow in the connected copper cabling between the antenna or pool equipment, satellite dish feed and the electrical supply ground rod.

To illustrate this in another way, ranchers and scientists have found that cows that are perpendicular to a lightning strike die because the electric current flows from the front hooves through the heart and body to the rear hooves, while cows parallel to the strike receive less current because the front hooves are so close, the voltage potential is much less.

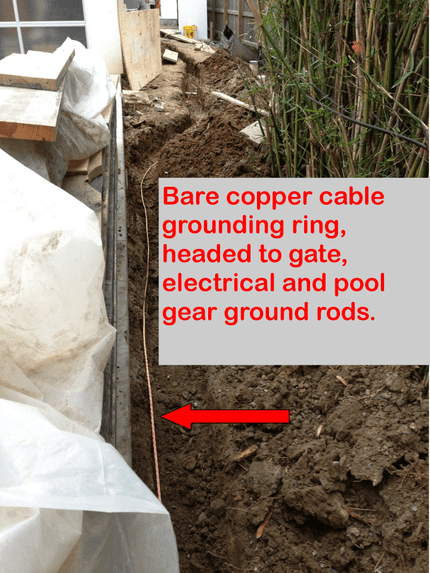

So if you are an estimator and you’re surveying the job you have to deal with this, you have to look for these things. Don’t leave this unfixed. Either reinstall the service by the electrical entrance and ground to the same ground rod or install a grounding ring (Fig 2) and connect the ground rods.

A ground ring is a bare copper cable (usually double ought) connected to the electrical ground rod, and is then buried in the dirt, encircling the building with multiple ground rods driven and connected every so often, or at a building corner, tying all ground rods together. All large and expensive jobs should have this, but on smaller jobs it’s not practical, so its probably not ideal for residential integrators.

If your job is small, no ring is called for. No separate ground rods, no ring required. On a million-dollar job, I would specify a full ring around the structure with ground rods at every corner, and a lightning control system not connected to the electrical ground ring. The lightning control system will have its own grounding system, though sometimes the lightning control systems are connected to the building electrical ground system. Just use common sense for what’s appropriate … you can never have too much common grounding and surge protection going on.

Coupling Grounding Systems

When coupling your grounding system to the earth it’s important to remember different types of dirt have different resistances. In my area of Louisiana, it’s no big deal if we have water 4 feet down. In rocky places or mountainous areas it’s much harder to couple to the ground and you might not even be able to drive a rod.

Polyphaser recommends using grounding strap laid across the rocky ground. I feel doing so is good, but the addition of Ground Enhancement Material (GEM by Erico) poured over the top of the strap may enhance the coupling. Also be sure to partner with a quality lightning rod control company, as they will know about the best methods of coupling in your area and they have the tools to measure ground resistance.

Intra-building connections, pool houses, guard shacks, gates, guest apartments or any other interconnected buildings should have their ground rods connected if they share a common electrical or electronic connection. As far as electronics interconnections between buildings, do not use copper or metal connections, including fiber with metal components or armor. Always use fiber in between buildings. Fiber is glass or plastic and does not conduct electricity and is really your only choice. If you don’t, you may be stuck installing all kinds of ground loop isolators and surge protection on both ends and dealing with poor signal quality, likely leading to a lot of extra truck rolls.

A Bit About Connections

There are many ways to connect to the ground rod. First thing, get rid of the electrician’s ground clamp as it’s not suitable for this application. Instead, use a clamp that is designed for clamping with high force. If you’re in need of a supplier, I use Storm Copper Grounding for all my ground wire, clamps and grounding buss bars. There, I gave you one of my valuable secret sources … I’d suggest Googling it.

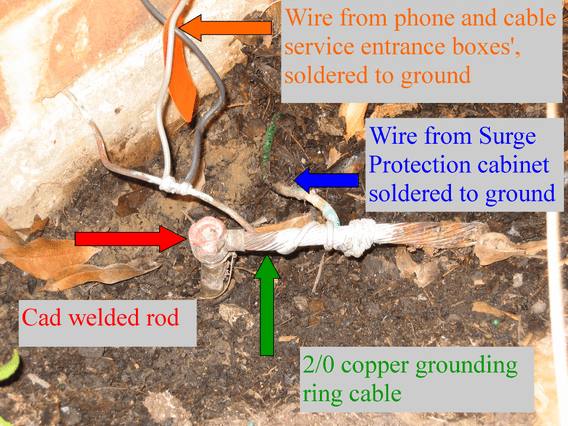

The next best way to attach the small grounding cables is to solder them to the main electrical ground wire connected to rod (see Fig 3). You must use a torch for this to get the copper super clean; It needs to look like a new penny! Use rosin core solder only, not plumbers solder.

The best way to do it, and the most fun and impressive is to cad weld the connections. I use Erico One Shot cad welders, which uses thermite to weld the copper to the steel rod. They must be clean and very importantly dry with no moisture present. Be sure to check safety precautions and use personal protective equipment to keep yourself safe during this step.

Cad welding makes a permanent connection, in fact it’s not considered a connection but a completely seamless piece of metal. All clamping systems for surge and lightning suppression must be periodically inspected and serviced.

Now you may be saying to yourself, “But Tom, all this stuff adds cost to my bids and besides that’s what insurance is for, and if I sell and install surge protection, and their house gets hit by lightning it will still be damaged.”

That is true, but instead of $500,000 dollars of damage, it might be $15,000 or even no cost at all. These are best practices used by industrial facilities, military installations, data centers and more. How would you feel, as the homeowner, if you paid $1.5M for your new Crestron automation, lighting, HVAC, etc. and you sustained $500,000 worth of damage?

I was called in for a job where the clients went without HVAC for a week, including no AV or lighting control, no TV or internet for weeks, and no lights in the house for more than a month. That’s just wrong and boy does it make our profession look bad.

A good rule of thumb is to spend at least 3% of the project’s budget on grounding and surge protection, or make it 5% and add fiber and media converters to your project.

Using these techniques will make you money because you won’t have to warranty failed parts or spend countless hours troubleshooting bad signals. Not every problem that arises from improper grounding can be traced to a lightning strike. Bad parts and bad signals all must be dealt with and cost you money since they can’t be paid for by the insurance settlement.

Plus, I might be the expert on the witness stand declaring you liable and incompetent for not following best practices.